Six Sigma Project and Quality management | DMAIC | DMADV | Structure | Phases

You Should Remember

Six Sigma‘s primary quality is to ensure superior quality of products by eliminating the imperfections in the processes and systems.

The method of Six Sigma initiated in engineering and manufacturing processes however nowadays it discovers its need in other industries as well. For a proper yet effective implementation of Six Sigma, it is significant to accurately allocate adequate budget as well as Resources.

Abbreviations:

CTQ: Critical to Quality

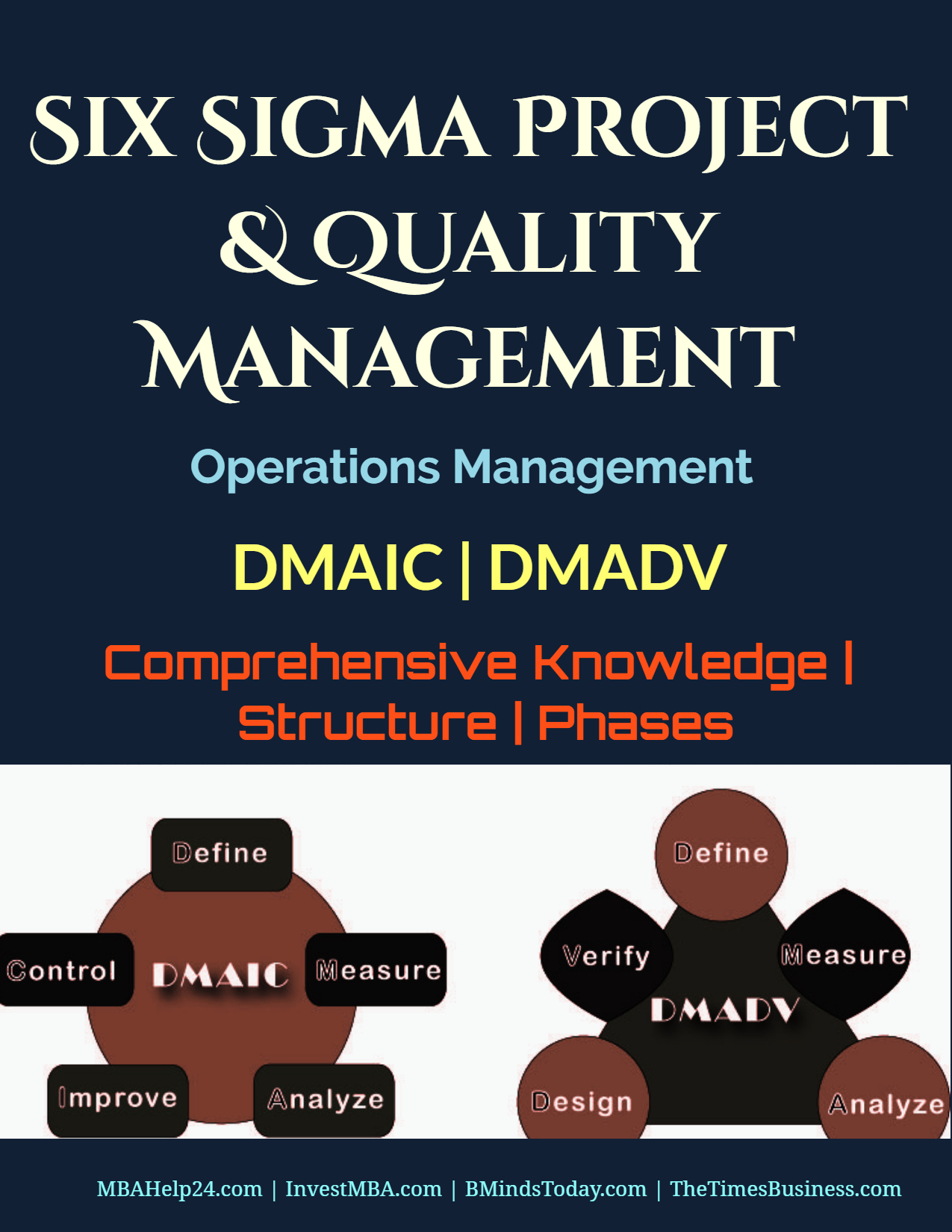

DMAIC: Define, Measure, Analyze, Improve, and Control

DMADV: Define, Measure, Analyze, Design and Verify

DFSS: Design for Six Sigma

VOC: Voice of Customer

Six Sigma is a strategic approach in business management which fundamentally aims at enlightening the excellence of quality processes by lessening and in due course eliminating the inaccuracies and disparities. In other words, the fundamental objective of the Six Sigma methodology is the implementation of a measurement-based process improvement through variation reduction.

The Six Sigma model was presented by Motorola in year 1986 nonetheless was promoted by Jack Welch who unified the Strategy in his Industry practices at General Electric.

Six Sigma‘s primary quality is to ensure superior quality of products by eliminating the imperfections in the processes and systems.

The process involves in Six Sigma benefits in strengthening the overall processes and systems by recognizing and in the end overcoming the obstacles.

The method of Six Sigma initiated in engineering and manufacturing processes however nowadays it discovers its need in other industries as well. For a proper yet effective implementation of Six Sigma, it is significant to accurately allocate adequate budget as well as Resources.

Here are the TWO Six Sigma methods that often implemented in an extensive quantity of organisations for betterment in quality related outcomes.

DMAIC mainly eMphasises on improving current Industry practices, while DMADV emphasises on building brand new strategies and programmes.

Quality Management Tools | Definitions | Methods and Systems | Plan | Policy | Control | Audit

Exploring DMAIC Phases In Six Sigma Project

DMAIC is a n acronym for five interconnected steps of a process improvement project: Define, Measure, Analyze, Improve, and Control (DMAIC).

Step 1- Define the Problem:

The very first stage in any Six Sigma project is to explain the problem and narrow its scope in such a way that the project team can attain measurable goals within a limited time. As part of the process, the feedbacks are cautiously taken and then monitored to recognize problem areas and their origin sources.

Define can include:

- Defining the customer, their Critical to Quality (CTQ) concerns, and the Core Business Process involved.

- Defining who customers are, what their necessities are for products and services, and what their anticipations are.

- Defining project limitations including the starting and ending steps of the process.

- Defining the process to be enhanced by mapping the process flow.

Step 2- Measure and learn the crucial facts of the existing process:

Once the problem is recognized, the team maps the process, collects data, verifies the quality of data, and prepares it for analysis.

Measure can include:

- Measuring the performance of the Core Business Process involved.

- Evolving a data gathering strategy for the process.

- Gathering data from several sources to determine types of defects and metrics.

- Comparing to customer analysis outcomes to determine shortfall.

Step 3- Analyze the data:

As soon as a process has been mapped, documented, and verified, the Six Sigma team can begin the analysis.

Analysis can include:

- Analysing the data to define root causes of faults and then finding opportunities for further improvements.

- Classifying gaps between current performance and goal performance.

- Recognizing bases of variation.

Step 4- Improve the existing processes:

The improvements are recognized based on the research and analysis done in the earlier phase.

Improvement can include:

- Enlightening the target method by planning inventive answers to fix and avoid difficulties

- Building advanced solutions using technology and discipline

- Evolving and organizing implementation strategy

Step 5- Control the processes:

This is the final phase in which teams create controls that enable the organisation to sustain and lengthen the improvements.

Controlling process can include:

- Monitoring the improvements to hold onto the procedure on the new course

- Needing the development, documentation, and implementation of a continuing monitoring strategy

- Institutionalizing the improvements through the modification of structures.

Exploring DMADV Method

The DMADV (Define, Measure, Analyze, Design and Verify) method is certainly the most popular yet prevalent of the Design for Six Sigma (DFSS) approaches. The DMADV builds off the DMAIC process as a data-driven Six Sigma technique primarily to reshape a challenging process.

Here’s the DMADV 5-Phase-Gate Structure:

Phase 1- Define the problem:

The very first phase focuses on defining the problem of the design activity, including internal and external customer requirements. This consists of a significant amount of Voice of Customer (VOC) collecting activities to form the design activities. This process benefits to design the strategies and processes which eventually ensure maximum level of customer satisfaction.

Phase 2- Measure:

The measuring phase basically deals with measuring the performance of the current process or product. It also deals with gathering appropriate data, and determining the customer’s requirements and allied specifications. This may possibly include a comParison between the current process and the new necessities. In a nutshell, this phase measures and then identifies parameters that are significant for quality.

Phase 3- Analyse:

The analysis phase fundamentally analyses the current performance data to segregate the problem and categorize the prospective advancement or improvement choices to better reach the external and internal customer requirements. In a nutshell, this phase analyses and develops high level substitutes to ensure superior quality.

Phase 4- Design:

This phase focuses on designing a new process as a result the problem is removed or new requests are met. This may contain restoring process, product or service offering implementing predictive simulations, and pilot testing to categorize the best design to accomplish the objectives.

Phase 5- Validate or Verify:

This is the final phase which emphasises validating that the new process is proficient of reaching the new process necessities. This may possibly consist of validating that the process or product design reaches goals for performance, and constancy to ensure the overall requirements can be accomplished over time in a non-test atmosphere.

To successfully implement DMADV, the process requires a number of key components: A measuring system, statistical analytical tools and a control scheme.

Concept Of Operations Management ?

Significance, Motives and Processes Of Operations Management | Inputs | Outputs

supply chain Management | Comprehensive Understanding | Driven Factors Behind SCM Popularity

Strategic Decision Variables In Supply Chain Management | Inventory | transportation | Facilities

The Bullwhip Effect In Supply Chains | Causes | Countermeasures

Vendor Managed Inventory | Overview | Features | Advantages | Concerns

Linear Programming | Checklist | Structure | Model | Assumptions | Applications

Quality Management Tools | Definitions | Methods and Systems | Plan | Policy | Control | Audit

http://www.mbahelp24.com/six-sigma-project-quality-management-dmaic-dmadv-dfss-phases/