The Bullwhip Effect In supply chains | Causes | Countermeasures | Demand forecasting | Lead-times | Batch ordering | Price fluctuations | Supply shortages

You Should Remember

It is very much clear that bullwhip effect can eventually lead to significant surges in costs and inventory levels all the way through the supply chain.

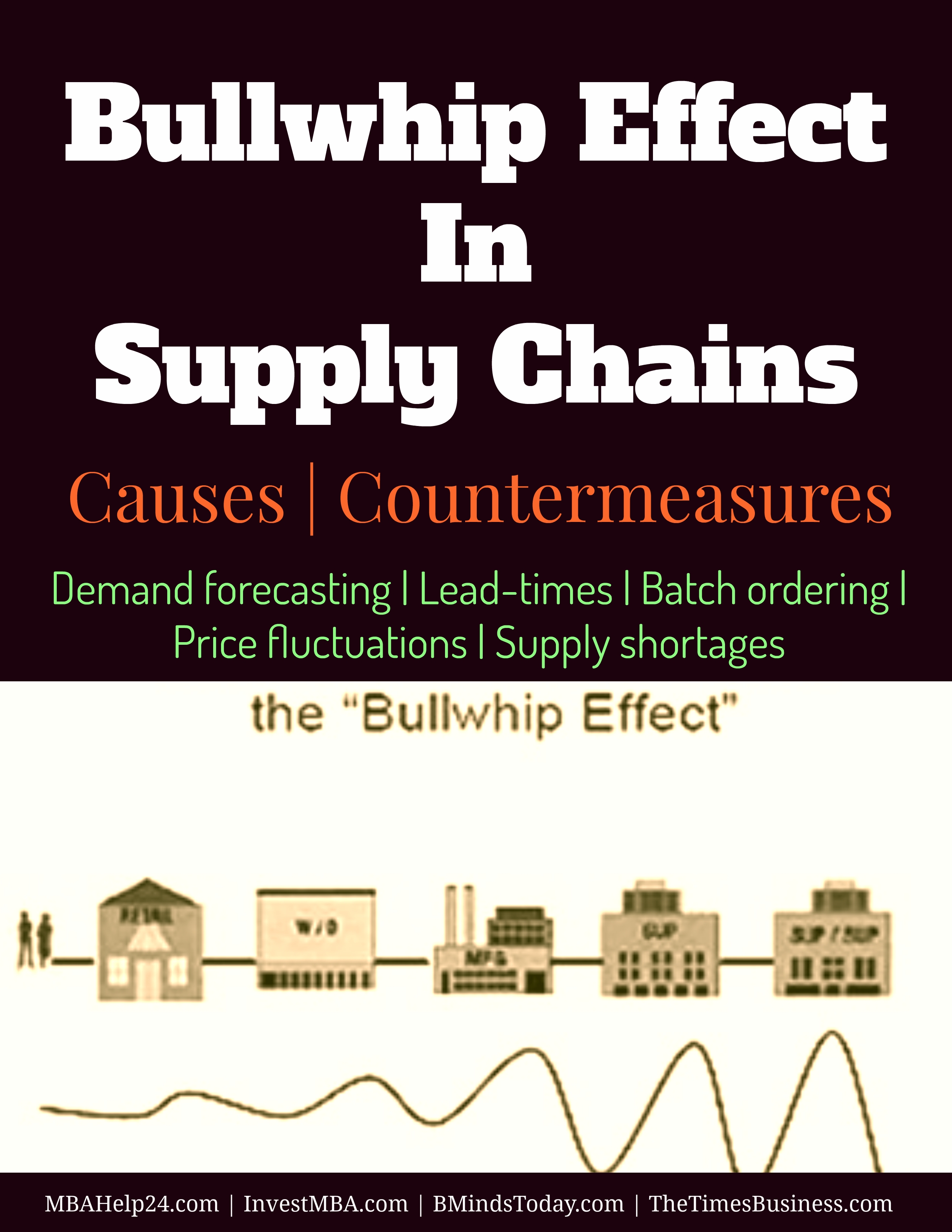

It basically refers to the tendency of the variability of demand rates to surge as they pass over the levels of a supply chain in the direction of manufacturers and raw material suppliers or dealers.

The Bullwhip Effect In Supply Chains

The Bullwhip Effect is one of the most well researched as well as analysed issues in Supply Chain management practices. This is a problem that has prevalently been detected in supply chains, in which the effect is considered to be an oscillation in the supply chain practices due to concerns caused by demand inconsistency.

The “bullwhip effect” is shorthand word for a dynamical occurrence in supply chains. It basically refers to the tendency of the variability of demand rates to surge as they pass over the levels of a supply chain in the direction of manufacturers and raw material suppliers or dealers.

Supply Chain Management | Comprehensive Understanding | Driven Factors Behind SCM Popularity

Bases of the Bullwhip Effect

It is very much clear that bullwhip effect can eventually lead to significant surges in costs and inventory levels all the way through the supply chain. In order to control or overcome the bullwhip effect it is highly essential to primary recognize its causes.

In the following section, the key factors that contribute to the bullwhip effect are being illustrated.

1. Managers’ overreaction to demand changes

The supply chain managers may not at all times be entirely balanced. They sometimes over-react or under-react to the changes in demand. They prevalently are over optimistic and sometimes confuse estimates with targets. Furthermore, decision makers in some cases over-react to the complaints filed by customers and their negative feedback.

2. Demand forecasting or demand signal processing

In order to control its target inventory level, each phase of the supply chain must forecast both the anticipated demand and the standard deviation of demand. This particular assessment can be carried out by undertaking several forecasting techniques. Any forecasting technique can potentially root the bullwhip effect, in which every person in the chain adds a certain percentage to the demand estimates. As a result, the outcome is no perceptibility of true customer demand.

3. Lead–times

The lead time is defined as the time it takes an order placed by the retailer to be expected at the retailer. Lead times can add to the bullwhip effect by enlarging the increase in variability due to the demand forecasting.

The lead-times are fundamentally made of two components; the physical delays as well as the information delays.

The lead-time is a core parameter for computing safety stock, and reorder points. The surge in variability is overstated with increasing lead-time. A mode to ease this problem is lead-time density. The information delay can be shortened by improved communication technologies s and other fulfilment lead-time (the physical lead-time) can be shortened by investment in production Technology, strategic supplier partnerships (i.e. supplier hubs.) or by get rid of channel intermediaries (i.e. direct channels).

4. Batch ordering

Economies of scale in ordering, production set-ups or transportation will to a certain extent visibly increase order variability. Larger orders end result in more variance.

5. Price fluctuations

Retailers repeatedly offer price reductions, vouchers or in-store promotions. This results in forward buying in which retailers buy in advance and in quantities that do not reflect their instant desires. Pricing strategies should clearly be linked to supply and replacement guidelines. On the other hand, it is not certain from marketing viewpoint whether the positive supply chain effect overshadows the potential negative marketing result.

6. Supply shortages

Customers order more than they need during a period of short supply, anticipating that the partial shipments they receive will be sufficient. Exaggerated customers’ orders make it hard for manufacturers to forecast the real demand level.

Strategic Decision Variables In Supply Chain Management | Inventory | Transportation | Facilities

Countermeasures to the Bullwhip Effect

To this point, we have discussed a number of the causes and effects of the bullwhip effect. In order to better understand and control the bullwhip effect, it would also be useful to understand the countermeasures. While the bullwhip effect is a widely held problem, several prominent businesses have been able to adopt and implement countermeasures to overcome ¡t.

The key countermeasures are illustrated in the following section:

1. Countermeasures to Managers’ overreaction to demand changes

Approaches to ease this problem include; sharing Point-of Sales data, sharing inventory and demand information, integrating ordering decisions and applying proper forecasting methods in the approved manner.

2. Countermeasures to demand forecasting or demand signal processing

It is imperative to realise that a substantial quantity of players in supply chains tend not to respond straight to the market nonetheless react to replenishment demand from downstream levels.

Absence of demand perceptibility can be addressed though accessibility to point of sale data. Centralised control of replenishment can overcome overstated demand forecasts.

3. Countermeasures to Lead–times

The information delay can be shortened by improved communication technologies s and other fulfilment lead-time (the physical lead-time) can be shortened by investment in production technology, strategic supplier partnerships (i.e. supplier hubs.) or by get rid of channel intermediaries (i.e. direct channels).

4. Countermeasures to Batch ordering

Order batching takes place in an effort to reduce ordering costs, to take advantage of transportation Economics

Reduction of set-up, ordering and handling costs is for sure a method to ease this issue.

5. Countermeasures to Price fluctuations

Pricing strategies should clearly be linked to supply and replacement guidelines. On the other hand, it is not certain from marketing viewpoint whether the positive supply chain effect overshadows the potential negative marketing result. High-low pricing can be substituted with everyday low prices (EDLP). Special buying deals can be applied in order to specify ordering at consistent breaks to improved harmonize delivery and purchase.

6. Countermeasures to supply shortages

A very modest countermeasure to manage supply shortage is to allocate products proportional to sales in previous periods rather than allocating based on what has been ordered.

Concept Of Operations Management ?

Significance, Motives and Processes Of Operations Management | Inputs | Outputs

Supply Chain Management | Comprehensive Understanding | Driven Factors Behind SCM Popularity

Strategic Decision Variables In Supply Chain Management | Inventory | Transportation | Facilities

Vendor Managed Inventory | Overview | Features | Advantages | Concerns

Linear Programming | Checklist | Structure | Model | Assumptions | Applications

Quality Management Tools | Definitions | Methods and Systems | Plan | Policy | Control | Audit

Six Sigma Project and Quality Management | DMAIC | DMADV | Structure | Phases

Kaizen Project | Benefits | Five S of Kaizen | Continuous Improvement

https://www.mbahelp24.com/bullwhip-effect-supply-chains-causes-countermeasures/